3/1/2023 Editors note: The 2023 version of NFPA 70, commonly referred to as the National Electrical Code (NEC) has been released. UL 1400-1 (Class 4 system requirements) and UL1400-2 (Class 4 cable requirements) are also available. Updates were made to the NEC and CEC adoption maps.

Class 4 is a new term that is part of the 2023 edition of NFPA70. NFPA70 is commonly called the National Electrical Code (NEC). Class 4 is defined in a new article 726. Article 726 is part of chapter 7 which is the section of the NEC that deals with special conditions. What is so special about Class 4?

Review of Power Limited and Non-Power Limited Circuits

Non-power limited circuits such as a traditional AC circuits or Class 1 circuits have no power limitation and are used to deliver lots of power to a load. These types of circuits require strict installation methods such as installation in conduit and in most locations require installation by licensed electricians.

Power limited circuits, which include traditional Class 2 circuits and Power-over-Ethernet (POE), typically have a 100W power limit. These circuits may send up to 100W of power on a pair of wires, but due to voltage drop on the wires they typically provide only 75W-90W of power to the actual load. These types of circuits are a lower risk than non-power limited circuits for risk of fire initiation and electric shock which allows for lower-cost wiring methods (Article 725) and may allow a lower labor skill level depending on the local jurisdiction. Power Limited circuits cannot share the same cable, enclosure, or raceway and Non-power limited circuits

Overview of Class 4 Power Circuits

A Fault-Managed Power System (FMPS) is defined as “a powering system that monitors for faults and controls power current delivered to ensure fault energy is limited.” Class 4 systems leverage Fault-Managed power (FMP) technology. These systems are not power limited and can deliver hundreds or thousands of watts of power. However, these systems intelligently limit the amount of energy that can go into a fault. Limiting the fault energy mitigates the risk of shock or fire and allows the installation of Class 4 circuits using methods like power-limited circuits.

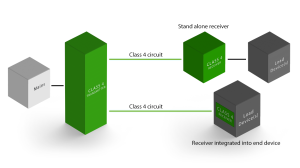

FMPS have two key components: the Transmitter and the Receiver. The Transmitter takes power from a power source and creates the Class 4 power circuit. The Transmitter delivers power on the Class 4 circuit to the Receiver. The Receiver takes the Class 4 power and converts it to the form of power that the load device needs. The receiver may be a stand-alone device that provides power to the end device or the receiver could be integrated into the end device.

Figure 1 – Class 4 System Diagram

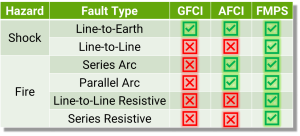

Shock and Fire Protection

Class 4 circuits may be AC or DC and up to 450V peak. Class 4 circuits are constantly monitored for fault events. Despite the higher voltages, FMPS have a similar risk for fire and shock when compared to power-limited circuits because the FMPS limits the fault energy. For example, if a person unintentionally comes in contact with the wires they may perceive a shock, but the system will limit the energy into the person to levels that will prevent shock injury and allow them to let go of the circuit. These systems can do this because they are built with electronics that can turn off power to the circuit within milliseconds, faster than a blink of an eye.

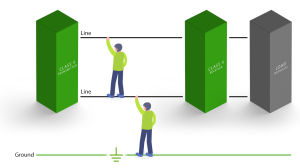

Class 4 systems have a unique capability that other devices such as a Ground Fault Circuit Interrupter (GFCI) do not have. FMPS not only limit fault energy for shocks that occur between the line conductor and earth, but they also limit the fault energy for line-to-line faults. See Figure 1. This means if someone accidentally touches both lines, the system will react to the fault and limit the energy into the person. Traditional power systems employing GFIs cannot react to line-to-line faults because GFIs cannot tell the difference between a person in contact with the wires and the load. FMPS can tell the difference between the load and a person in contact with the lines.

Figure 2 – Shock Fault Conditions

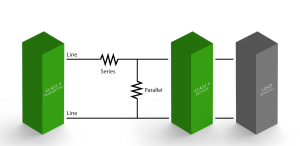

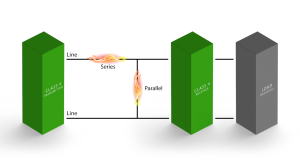

In addition to shock, Class 4 circuits also limit the risk of fire. This is accomplished by limiting the amount of energy into an arc fault as well as managing resistive faults. FMPS detect or prevent dangerous arcs that can lead to fire, both line-to-line as well as in-line. Resistive faults are limited to 100W for line-to-line faults which limits the amount of heat that can be generated to the same amount of heat allowed in a traditional Class 2 circuit. It is likely that some FMPS will manage series faults by either limiting series faults to 100W or using specialized connector hardware with proper fire ratings to limit the risk of fire from a series resistive fault.

Figure 3 – Resistive Fault Conditions for Fire Risk

Figure 4 – Arc Fault Conditions for Fire Risk

These intelligent systems limit the energy into a fault and typically they can re-enable power automatically to the circuit once the fault has been removed and a defined amount of time has elapsed. FMPS provide the power capability of a power circuit with the hazard levels of a power-limited circuit enabling new ways of distributing power.

Table 1 – Summary of Fault Protections for GFCI, AFCI and FMPS

GFCI: Ground Fault Circuit-Interrupter

AFCI: Arc Fault Circuit-Interrupter

Article 726

The new Article 726, part of the 2023 NEC, explains the requirements for Class 4 equipment and cables as well as the installation methods required.

UL 1400-1 Equipment Requirements

Transmitters and Receivers will need to be listed devices to be installed as Class 4 devices. To be listed as Class 4 devices, each device will need to meet the requirements of UL 1400-1. 1400-1 is a UL Outline of Investigation expected to be published later this year. 1400-1 includes the detailed requirements an FMPS needs to meet. These requirements include the shock and fire requirements unique to Class 4 as well as general requirements for product safety such as grounding and isolation.

UL 1400-2 Cable Requirements

In addition to the device listing requirements, the cables used with Class 4 systems must be listed Class 4 cables. UL has published an Outline of Investigation with the requirements for Class 4 cables: UL 1400-2. It includes requirements such as insulation requirements, materials allowed, wire gauges allowed, etc. Class 4 cables must use copper conductors and may be 6AWG to 24AWG.

Cables for limited-power and fault-managed power systems are now part of Article 722.

The new Article 722 will combine cable requirements for Class 2 and Class 3 cables and introduce a new cable classification (Class 4) into a single article in the 2023 NEC. This unification was done to eliminate redundancy across multiple articles and make it easier for users to find the information they need. It was also renamed to accurately reflect what Article 722 now represents: Cables for Power-Limited Circuits and Fault-Managed Power Circuits.

Installation requirements

The big promise of Class 4 systems is that because of the fault management the installation methods do not need to be as strict as NEC Chapter 3 methods to be considered a safe installation. Article 726 allows for the installation of Class 4 circuits without conduit in most situations. Without conduit, Class 4 circuits can be installed much faster and allow better move/add/change capability for power distribution infrastructure.

Class 4 systems may also be installed alongside many types of power-limited circuits such as Power-over-Ethernet (PoE) and data circuits like Ethernet. Class 4 cables may be installed in the same cable, enclosure, or raceway as Class 2 circuits. The flexibility of Class 4 to install power delivery alongside communications greatly simplifies installations by converging power and data to the same pathway.

Article 726 contains some requirements for the connection hardware used for Class 4 circuits. They must be listed with the appropriate ratings. The connectors used may not be interchangeable with other non-power limited circuits at the same location. This is to prevent someone from accidentally plugging a non-power limited circuit into Class 4 wiring and thus creating a hazardous condition. Class 4 junctions and connectors must also be guarded to avoid incidental contact.

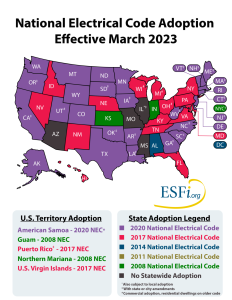

Local Code Adoption

Figure 5 – NEC Adoption Map

Figure 6 – CEC Adoption Map

The National Electrical Code (NEC) and Canadian Electrical Code (CEC) are updated and published every 3 years. The CEC follows 1 year behind the NEC. The latest editions are 2023 and 2021 respectively. Once the codes are published, local jurisdictions must choose to adopt the latest code before it can be enforced in that state. The Authority Having Jurisdiction (AHJ) within each region is the entity that is responsible for enforcing installation requirements and they may only enforce code requirements that their state (or local jurisdiction) has adopted. Not all states adopt the code at once. In fact, many states are still using older editions of the code and some states do not have state-wide adoption but rely on local adoption.

This means that Class 4 circuits will not be an enforceable method of installation within a given state until that state or local jurisdiction has adopted the 2023 code. It is expected to take several years before Class 4 circuits are enforceable within all states.

One question that remains to be answered is what the permitting and licensing requirements for Class 4 circuits will be. This will be up to each state legislature to decide. Just like each state has different permitting and licensing requirements for limited-power circuits like PoE, each state will set its own requirements for Class 4 circuits.

The NEC is only applicable in the United States, and the CEC is only applicable to Canada. Other countries have their own electric codes that may or may not be applicable to a given FMPS. For other countries, each system should be evaluated for compliance with the local electric codes.

About VoltServer

At VoltServer, we are revolutionizing the way electricity is distributed with our pioneering Digital Electricity™ solutions. As the first company to invent, patent and commercialize the distribution of electricity in a natively digital format, Digital Electricity™ is recognized as a dedicated section in the 2023 National Electric Code and Underwriters Laboratory which is referred to as “Fault Managed Power Systems” or “Class 4 Power,” signifying its importance and potential impact. VoltServer has a global presence with numerous circuits installed worldwide in various prestigious venues such as sports stadiums, office towers, hotels, airports, macro towers, warehouses, and agriculture facilities.

References

Sources

Electrical Safety Foundation

Canadian Electrical Contractors Association

National Electrical Code (NEC), current edition 2023

Article 725: Class 1, Class 2, and Class 3 Remote- Control, Signaling, and Power-Limited Circuits

Article 726: Class 4 Fault Managed Power Systems

Audio/Video, Information and Communication Technology Equipment – Part 1: Safety Requirements

Audio/video, information and communication technology equipment – Part 1: Safety requirements (Bi-national standard, with UL 62368-1)

Audio/video, information and communication technology equipment – Part 1: Safety requirements

Outline of Investigation for Fault-Managed Power Systems (Class 4 systems)

Outline of Investigation for Fault-Managed Power Systems (Class 4 cables)