Industrial edge networking stands ready to support increasing density, bandwidth, latency, distance, and cybersecurity requirements as Industry 4.0 practices take hold.

By Rodger Hyle

As it enables smart technology integration into operational processes, Industry 4.0 is changing entire industries for the better.

Through Industry 4.0 practices, data-driven smart technologies like generative artificial intelligence (AI) and augmented reality (AR) are helping organizations and their people work more efficiently and sustainably. The result: better quality, more optimized workforces, elevated operations, less risk, and fewer failures.

New Networking Requirements Driven by Industry 4.0

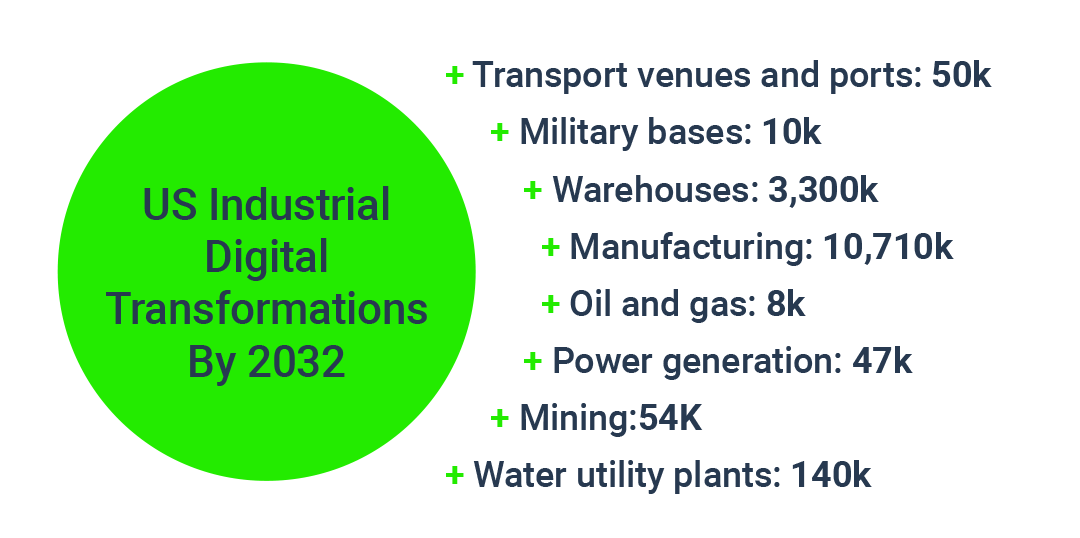

While Industry 4.0 infiltrates industrial sectors, industrial networking challenges also begin to arise.

The lines between operational technology (OT) and information technology (IT) continue to blur as digital and physical operations become intertwined and real-time data from devices and sensors is leveraged to increase visibility.

This transformation establishes new networking requirements.

Density

Device counts are increasing exponentially. Last year, 15.9 billion Internet of Things (IoT) devices were in use; by 2030, that number is projected to surpass 32.1 billion. Industrial networks must be prepared to handle this ongoing acceleration in device density.

Bandwidth management

More devices mean more data collection and transmission. By 2025, IoT devices are estimated to generate nearly 79.4 ZB of manufacturing data each year. The amount of data being generated and shared to support Industry 4.0 can overwhelm existing infrastructure. Industrial networks must be prepared to manage bandwidth to make sure data and power are accessible.

Latency

Because devices communicate in real-time, low latency is critical to enable responsive communication and avoid delays or interruptions. Industrial networks must eliminate these communication delays and lags.

IoT PoE (Power over Ethernet) switches and industrial edge compute elements need to be located at the network edge to ensure ultra-low latency (uLL) and optimal bandwidth utilization for the types of emerging applications mentioned earlier, such as AI and AR.

Delays of any kind can negatively impact production and operations, uptime, and decision-making—especially when split-second choices matter (in predictive maintenance, autonomous robots, or quality control, for example).

Power and data distance

For optimal performance, sensors and devices must often be placed closer to the edge—which can be farther than 100 m from traditional IT-based IDF locations, impacting data and power delivery strategies.

Provisioning power can be a significant obstacle due to the high costs and deployment delays associated with local power. Industrial networks should be able to support power and data distances of hundreds or thousands of feet from a centralized core or MDF location(s) to the industrial edge.

Cybersecurity

Critical IT and OT data and infrastructure require protection to ensure safe and resilient operations and avoid downtime. Industrial networks must be prepared for and able to mitigate the risk of a breach or attack.

The Power of Industrial Edge Networking

The answer to overcoming many of these challenges can be found in industrial edge networking. This fiber-/power-deep network topology is prepared to handle:

- Higher density

- More bandwidth

- Lower latency

- Longer power and data distances

- Improved security

It bypasses traditional telco rooms and drives fiber and power deeper and farther into the network, enabling switching in work/cell areas instead of in a telecommunications room (TR).

Industrial edge networking allows data to be processed and analyzed right where it’s produced to reduce the need to send data to the cloud or to a centralized data center for processing and analysis. This enables:

- Faster response times

- Confident real-time decision-making

- Improved connectivity by minimizing latency

- Simple and responsive scalability

- Improved data security

- Higher levels of reliability

Creating Simplified and Scalable Edge Networks

VoltServer’s Digital Electricity™, a fault-managed power solution (FMPS), drastically reduces the complexity, time, and costs associated with edge-based networking deployment.

Digital Electricity can overcome the challenges associated with supporting connected industrial devices today and in the future by giving network designers the freedom and flexibility to locate modular IDF/TR resources anywhere within the industrial environment, creating simplified yet scalable networks.

As new technologies and devices move closer to the source of data generation—the network edge— Digital Electricity can ensure that more bandwidth and power are also accessible there.

Learn more at https://voltserver.com/industrial-manufacturing/

Rodger Hyle is the director of market development at VoltServer.